Challenges in Implementing Visual Factory: Overcoming Common Obstacles

By admin-2

You know, diving into a fresh work method can sometimes feel like wading through thick mud—everything’s challenging, and it’s hard to see the end. But what if we shift our glasses a bit and see it as a golden ticket to refine our business? Visual factory software, in my eyes, is just that ticket. Not only can it speed up enhancements, but it’s also a savvy way to cut back on expenses in the long run. And hey, while the journey to integrate visual factories might seem daunting, remember: with a bit of elbow grease and some solid prep, you’ve got this!

It’s not a matter of whether you should go down this road, it’s a matter of when you do

Table of Contents

When you’re considering going down this road, it’s important to consider all the benefits that visual factory can bring. The first and most obvious benefit is that it will make your supply chain more efficient. This means less waste, less rework and better quality products for your customers.

Another reason why you should consider implementing a visual factory is because it allows for more collaboration between teams throughout the entire production process — from design to manufacturing to assembly to shipping. With traditional processes, these groups don’t always work together very closely; but with visual factories they share information on a regular basis, which helps them make better decisions together (and faster).

Visual factory also gives workers more autonomy over their own tasks, so they can focus on making big improvements instead of just doing what they’re told without thinking twice about whether those instructions make sense or not.

It’s going to be a challenge

Alright, here’s the deal: you’ve got to be primed and ready, with a solid game plan in hand. But equally important? Surrounding yourself with a stellar team – folks who won’t buckle under pressure and will have your back when the road gets bumpy. And trust me, there’ll be twists and turns. Nothing ever pans out exactly as we imagine, and you know what? That’s all part of the adventure!

It requires new skills

You know that age-old adage, ‘It takes a village to raise a child’? Well, when you’re diving into setting up a Visual Factory, it feels a lot like that. You truly need the whole team on board. Every member of your staff plays a unique part, and they’ll need to understand not just their role, but also how they’re a piece of this larger puzzle. Only together can you reach that shared success. This will require training them on new processes, tools and technologies that support their efforts toward achieving better results within their departmental goals or even across multiple departments within your organization (if applicable).

You need to embrace change

You know, I’ve come to realize that even with the best visual factory design, change is a constant companion. And while it might be a little wild and unpredictable at times, it isn’t something we should shy away from. Actually, rolling with the punches and embracing change often makes things simpler in the long run. It gives us that edge to adapt to surprises or seize new chances that inevitably pop up. What’s vital to remember is that not all changes are painted with the same brush: some are blessings in disguise, others challenge us, and a few might push us out of our cozy little bubbles. But that’s life, isn’t it?

You need to make sure everyone is on board with this new way of working

Implementing a visual factory is a significant change for your organization. It’s important that everyone understands what the VF is and how it will benefit them, as well as the company.

As you’re planning your implementation, make sure that you’re communicating with all stakeholders–not just those involved in manufacturing or IT, but also finance and HR teams (or whoever else may be impacted by this change).

New methodologies will be required

Implementing a Visual Factory will require new methodologies. The first step is understanding how to implement these new methods, and then convincing people at all levels of the organization that this is the best way to do things.

The benefits of adopting a Visual Factory are clear: shorter lead times, higher quality and more efficient production processes. With these benefits in mind, it should be easy for anyone on your team to understand why you want them on board with the change (and if they aren’t convinced yet, there are ways around that too).

A lot of planning will be required

You know, one thing I’ve always believed is that planning is the secret sauce behind any successful endeavor. And this belief has only grown stronger during my time in the IT world. For something as intricate as a VF implementation?

Planning is not just a one-time thing you tick off the list. It isn’t confined to just the kickoff or wrap-up. Instead, it’s a continuous heartbeat that persists, guiding every step and phase of your project’s journey. This means that even if you’ve already done some initial planning (or maybe even some significant amount), there may still be room for improvement when it comes down to actually implementing VF into your environment!

Visual factory software will be helpful

Visual factory software like LineView will be helpful in managing the whole process. With visual factory software, you can manage your supply chain, production line and quality control. You can also use it to keep track of inventory levels and other data related to your business operations.

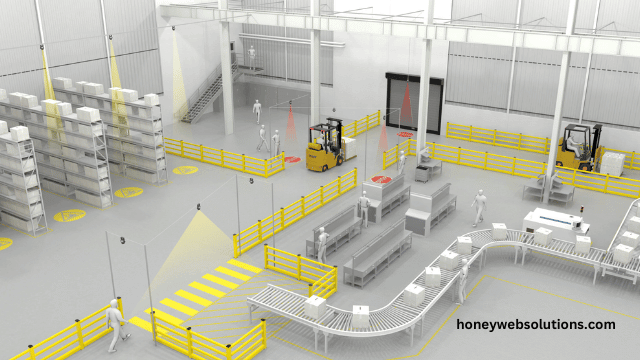

Visual Factory is a relatively new concept in manufacturing businesses where it helps in managing all aspects of production activities including planning & scheduling as well as execution & control using real-time data from multiple sources like ERP (Enterprise Resource Planning), MES (Manufacturing Execution System), WMS (Warehouse Management System) etc.

The benefits of implementing visual factory can be great for your business

Have you ever considered the power of a visual factory? From my experience, it’s like giving your manufacturing process a whole new lease on life. Not only does it cut down expenses, but it can also ramp up the quality of what you produce. And who doesn’t want a smoother, more efficient workflow? If you get the right tools and methods on board, I genuinely think it can revolutionize your business.

The benefits of implementing visual factory are numerous:

- Improved Quality – Visualization helps ensure quality control at every stage of production by providing a clear picture of what needs to be done next or how far along each process is at any given time. This means less waste as well as fewer errors because there’s no ambiguity about what needs attention next or when something has been completed correctly (or incorrectly).

- More Efficient Processes – Visualization also makes it possible for workers to perform tasks more efficiently than ever before since they don’t have to wasted time trying to figure out what steps need doing next based on incomplete information from previous stages; instead they simply follow their automated instructions which show them exactly how much progress has been made thus far toward meeting goals like completion date targets or target costs per unit produced.

Conclusion

It’s been an enlightening journey exploring the ins and outs of implementing a visual factory, hasn’t it? I truly believe it can revolutionize businesses. But like anything worthwhile, it comes with its challenges. As you ponder whether it’s a good fit for your business, take a moment to weigh all these aspects. Best of luck in your decision-making!